Techcomlight delivers Powerdaylight Cradle Eco to PepsiCo Veurne

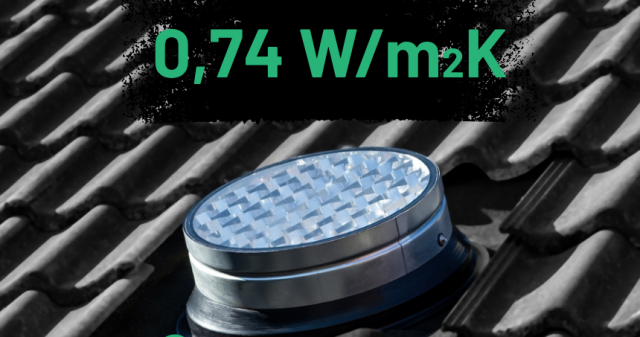

Techcomlight has recently made an important contribution to the sustainability of PepsiCo’s production facility in Veurne, Belgium. In total, thirty Powerdaylight Cradle Eco daylight systems were supplied and installed. These innovative daylight solutions stand out thanks to their excellent insulation value of just 0.7 W/m2K, contributing to both energy savings and improved comfort within the factory.

Sustainable continuation of earlier collaboration

The installation in Veurne was completed more than 15 years since the first collaboration between Techcomlight and PepsiCo. At that time, the chips factory in Broek op Langedijk (the Netherlands) was equipped with standard Powerdaylight systems combined with TechLED. With this, PepsiCo took early steps towards a more sustainable production environment.

Benefits for continuity and efficiency

A key advantage of the TechLED is that production does not need to be halted for replacement or maintenance. This can be carried out easily from the roof, without disrupting the production process. In addition, the integrated TechLED is designed for an exceptionally long lifespan, ensuring PepsiCo can rely on a durable and low-maintenance lighting solution.

Contribution to PepsiCo’s sustainability goals

With this investment, PepsiCo once again underlines its commitment to sustainability, energy efficiency, and innovative technologies across its production facilities. Techcomlight is proud to contribute to the future-proof ambitions of this international food company with its Powerdaylight brand.